July 2021 TheShift e-newsletter

Free Webinar - Water Use Intensity in Energy Creation | New Product & Business Model Innovation

Free Webinar—Sustainable Water Management For Decarbonizing Fossil Power Generation

Thursday, July 15, 2021—1:00pm EDT

Wknight94 talk, CC BY-SA 3.0, via Wikimedia Commons

Water use intensity is projected to increase for many of the leading decarbonization pathways for fossil power generation. These include fuel switching (e.g. biomass, hydrogen) and carbon capture and storage (CCS). In many parts of the US, water scarcity is already a key consideration both for management of current systems as well as for planning of future investments. This motivates additional effort at reducing power plant water intensity through operation improvements, technology selection, and sourcing of non-traditional waters. This webinar will focus on understanding the water consumption and global warming potential of various power production routes today and tomorrow to meet future energy demands.

Presenter: Timothy J. Skone, P.E., DOE National Energy Technology Laboratory

Mr. Skone is a Senior Environmental Engineer within the Department of Energy, National Energy Technology Laboratory’s Systems Engineering and Analysis Directorate. He leads Life Cycle Analysis Research efforts within the Office of Fossil Energy on carbon utilization technologies, methane emissions from the natural gas value chain, alternative transportation fuels, advanced power generation systems, and energy water impacts. He is the primary author on multiple natural gas and coal related life cycle analyses published by the Department of Energy. He also leads research on energy resource availability, water scarcity, integration of biomass and fossil energy resources, and strategic energy concepts for new programs. Mr. Skone is an elected member of the Society of Environmental Toxicology and Chemistry (SETAC) North American Life Cycle Analysis Interest Group, SETAC liaison to the American Center for Life Cycle Analysis, member of the University of Michigan Global CO2 Initiative Advisory Board, and founding organizing member of the Federal LCA Commons. Mr. Skone has 21 years of experience in the field of energy analysis and is a graduate of the Penn State University.

Bringing A Renewable Fuel Alternative to Market: How LCA Data Helped Biofine Develop New Technology, Win Industry Support

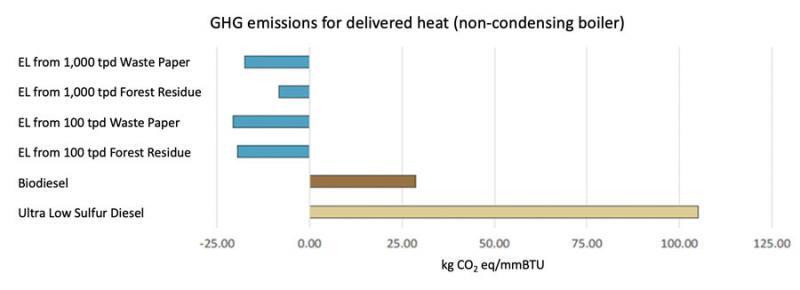

Over 5 billion gallons of heating oil are burned in the US annually, contributing significantly to greenhouse gas (GHG) emissions and climate change. To address these issues, chemical engineer Dr. Steven Fitzpatrick sought to develop a new biofuel alternative that would reduce the resulting GHG emissions without significant changes in behavior or additional cost outlay by consumers or suppliers.

Biofine Developments Northeast (BDNE), a company founded by Dr. Fitzpatrick, has developed and patented a process for converting cellulose waste into a liquid biofuel alternative, ethyl levulinate (EL). Known as Biofine EL, it can be used in existing oil-based heating systems and delivered through existing supply chains at competitive cost.

To support Dr. Fitzgerald’s technology and market development efforts, EarthShift Global consultants conducted two life cycle assessment (LCA) projects that...

How HP Used Anticipatory LCA to Develop Innovative New Products and Business Models

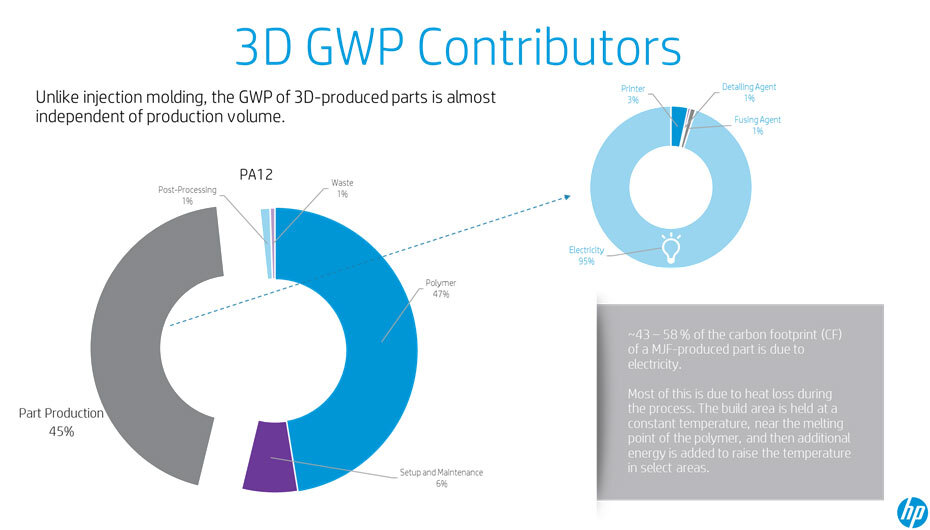

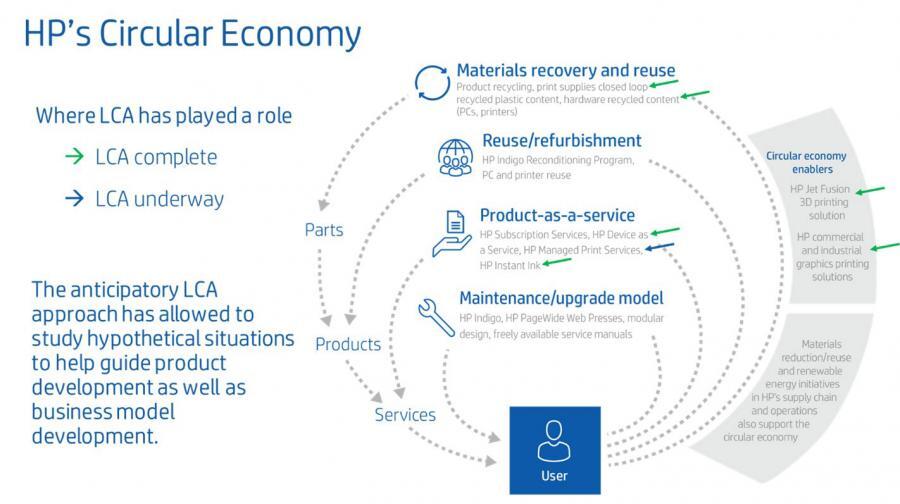

HP Inc. has a long history of sustainability initiatives with LCA (Life Cycle Assessment) at their core. EarthShift Global had the privilege of supporting HP using an Anticipatory LCA approach when they first introduced their 3D printing technology. The insights gained from the LCA have allowed HP to study hypothetical situations to help guide product development and provided impetus for new business model development.

The initial study compared several 3D printed parts with the same parts made using injection molding. An immediate finding of the study was high energy consumption by the 3D printer. This was unexpected by the team, as the printer is based on ink-jet technology which is considered to have low energy consumption. The team immediately started work to reduce the energy consumption.

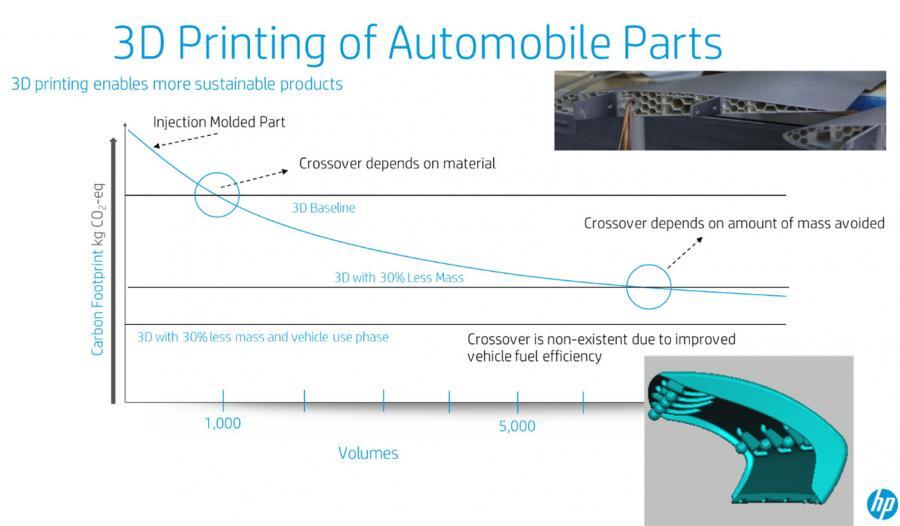

The main study showed what HP was expecting: that the impacts of 3D printing were lower than injection molding and higher after some break-even point—similar to the economic situation. Adding consideration of the decarbonization of the energy grid, however, we found that the 3D parts were better for many more parts, and even at high volumes were essentially equivalent in impact.

3D printing also allows designers to reduce the weight of a part while still performing the same function and the auto manufacturer we worked with suggested that a 30% mass reduction was achievable with some of their parts. This reduction again gives the 3D printed parts an impact benefit over larger volumes of parts. But since the reduction in mass is part of an overall effort to improve efficiency, if the efficiency improvements are taken into consideration the 3D part is by far a winner.

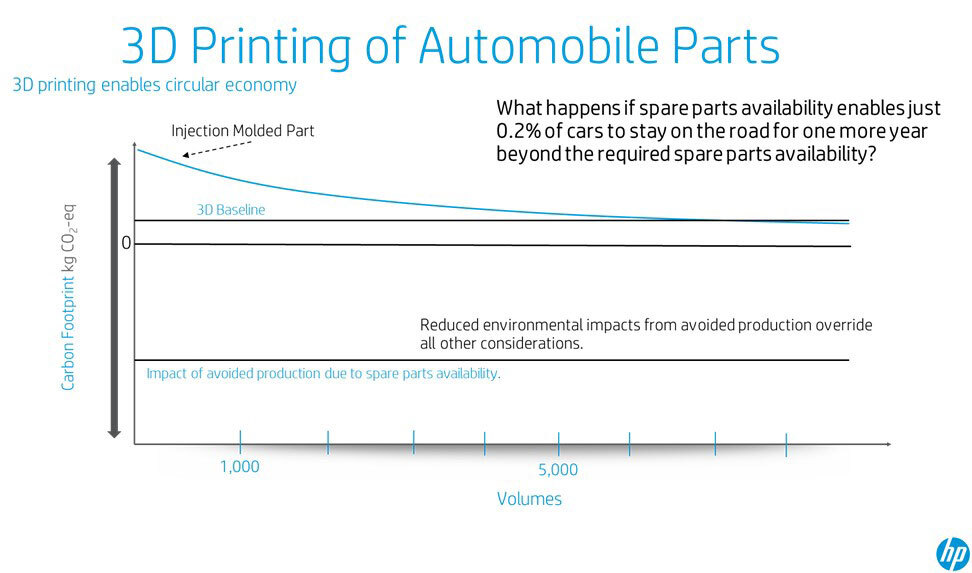

Another benefit of 3D printing is the ability to print very low volumes on demand. Team members on both the HP and EarthShift Global side had recently had to replace dishwashers for a single, obsolete broken part, so the topic was fresh to mind. We looked at this by considering that a very small number of cars might last one year longer if a broken part could be 3D printed. The benefit of not having to make another car was significantly more than the impact of making the part at any volume.

This insight went farther than anticipated, as HP recognized the equipment life concern with their own products. The brainstorming around longer equipment life led to several new business models, including printing as a service and device-as-a-service for PCs.

In summary, Anticipatory LCA as applied to HP Inc. 3D printing, was instrumental in identifying opportunities to reduce impact on the environment, guide new product development, improve the customer experience and foster development of a new business model.

Upcoming Training

Last Chance!

Anticipatory LCA - From Concept to Application

(3 hrs.)—July 20-21 (New Dates!)

$750 per person

Anticipatory LCA is an advanced LCA approach designed to improve decision making in the early stages of the design process. LCA researchers have developed several Anticipatory LCA techniques which enable application of LCA early in the research and development phases where uncertainty, but also potential for improvement, is greatest. Anticipatory LCA can be applied as a design tool to explore the environmental variability of alternative technology configurations and applications. This is especially beneficial in the design phases when data is uncertain and fast changing and limits a full traditional LCA.

This course will provide an introduction to the concepts of Anticipatory LCA, and an exploration of the applications of the concepts through industry case studies. In this interactive online course, participants will also have the opportunity to apply Anticipatory LCA concepts to their own case study. Get started applying the concepts to your own situation with an all-star group of instructors: Lise Laurin, Valentina Prado, Tom Seager and Equilibrio co-founder Tom Etheridge.