The Invoice of the Future

Supply chains are fragmented - disconnected by all but one thin piece of connective tissue.

Supply chains are fragmented - disconnected by all but one thin piece of connective tissue. There is a vague sense of connectivity as costs are accumulated while goods move from point of origin up a supply chain towards a final customer. We assume that (strategic pricing aside) what the consumer pays for the goods is additive all the way the supply chain – that the final price is COGS + Margin X all the way down.

There is a “paper trail” – a series of invoices that when divided by the unit sold at each step along the way, should add up to a final cumulative cost. We could audit this trail, if price transparency was an acceptable business practice.

What is needed is this kind of traceability – a paper trail - for the environmental and social cost of the goods we purchase as well. Where is the environmental invoice that travels with goods as they move up the chain?

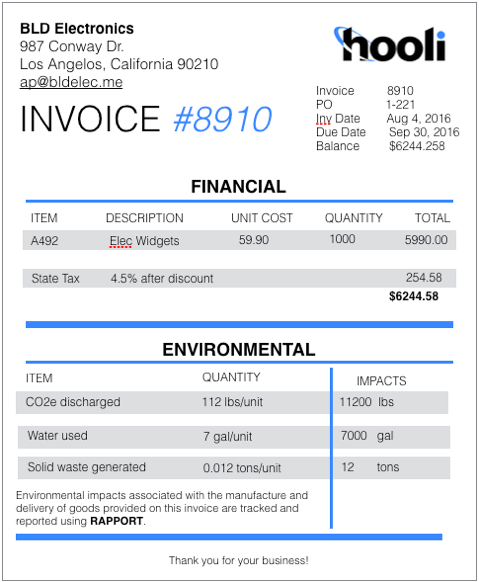

It’s here.

One of the major shifts happening in sustainability is the integration of environmental impact data with the procurement department. Environmental performance is now part of supplier ranking to a larger degree, and, to a lesser degree, is part of the decision process and contract negotiations. What I hear from procurement personnel around the Fortune 100 is “all things being equal, a favorable sustainability score moves the needle towards one supplier over another.”

Of course, all things are never equal so this is mostly lip service and marketing.

And, anyway, the data is not available. Instead, these procurement professionals are armed with models and surveys. Supplier Surveys reveal shapes in the land, not the land itself. Surveys typically convey some internal policies and procedures, maybe some company-wide carbon metrics, but rarely if ever do they include product–level data at any meaningful frequency. When asked, the most common answer is “unable to answer.” These surveys are glances in the rearview mirror. Actual environmental impact data is nearly impossible to gather especially as you move beyond Tier 1 suppliers thanks to missing market levers and out-sized technology.

What is needed is a mechanism to share the environmental metric of goods into, through, and up the entire supply chain. The financial invoice is as good a model as any to accomplish this. In fact, utilizing the financial invoice itself provides us with a consistent format, utilizes an existing (and valuable) communication platform, and integrates sustainability deeper into procurement and CFO’s purview.

In this example, we see the financial costs of “Electronic Widgets” as well as the environmental “costs” for the energy, water and waste required to produce said “Electronic Widgets.” Each of these impacts (energy, water, waste) are pulled from utility accounts, greenhouse gasses and other impacts are calculated to accepted national and international standards, and finally, the entire footprint is divided by its production and then allocated to the customer based on the number of units produced.

It’s alarmingly simple to do on a one-to-one basis. But within the web of supply chains, with a myriad of many-to-one, one-to-many and many-to many relationships, there is enormous complexity and opportunity. The data creates a perfect footprint to follow.

Technology is a big part of the solution. I think we have solved that. What’s left is a cultural shift that includes genuine supply chain engagement around issues of environmental and social impact. I think leveraging the invoice can serve as a kind of lubricant for this kind of data collection.